engineering plastic

Engineering Plastic: The Backbone of Modern Industrial Innovation

- Engineering plastics are high-performance materials used in demanding industrial applications due to their superior mechanical, thermal, and chemical properties. Unlike commodity plastics, engineering plastics offer greater strength, durability, and resistance to environmental factors, making them ideal for use in automotive, aerospace, electronics, medical devices, and industrial machinery. This article explores what engineering plastics are, their key properties, types, applications, and benefits.

What is Engineering Plastic?

- Engineering plastics are a group of plastic materials that have better mechanical and thermal properties than standard or commodity plastics. These plastics are designed to perform reliably under mechanical stress, high temperatures, and chemical exposure, making them suitable for engineering and industrial use. Unlike metals, engineering plastics are lighter, corrosion-resistant, and easier to process, which significantly reduces manufacturing costs and improves efficiency.

Advantages of Engineering Plastics Over Traditional Materials

Lightweight

Reduces the overall weight of components, leading to energy efficiency, especially in transportation.

Corrosion Resistance

Unlike metals, engineering plastics do not corrode or rust, ensuring a longer service life.

Design Flexibility

Can be easily molded into complex shapes, reducing part count and simplifying assembly.

Conclusion

Engineering plastics have revolutionized industrial manufacturing by offering a perfect balance of strength, durability, and cost-efficiency. Their adaptability across multiple sectors—including automotive, aerospace, electronics, and medical—demonstrates their importance in modern engineering solutions. As industries continue to seek lightweight, high-performance, and environmentally sustainable materials, the role of engineering plastics will only grow stronger in the years to come.

Why Choose Us?

At Euro Rubbertech International LLC, we understand that choosing the right material is crucial for the success of your engineering projects. Our premium engineering plastics offer exceptional strength, durability, and precision—making them the perfect solution for a wide range of industrial applications.

Superior Material Quality

We source and manufacture engineering plastics with outstanding mechanical properties, chemical resistance, and thermal stability to ensure your products perform reliably under the most demanding conditions.

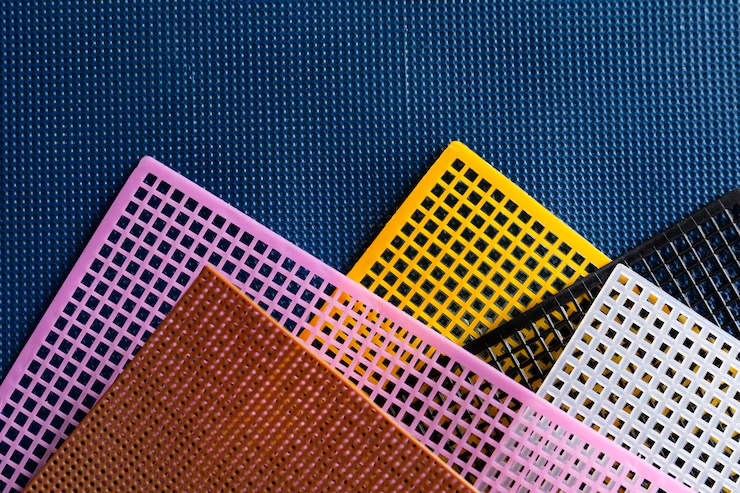

Wide Range of Products

From nylon, acetal, and polycarbonate to PEEK and PTFE, we provide a comprehensive selection of engineering plastics tailored to meet specific application requirements.

Custom Sizes & Specifications

Our engineering plastics are available in various grades, thicknesses, and forms—allowing you to find the perfect fit for your design and manufacturing needs.

Precision & Consistency

Our manufacturing processes guarantee tight tolerances and consistent quality, ensuring your components function flawlessly in critical applications.

Expert Technical Support

At Euro Rubbertech International LLC, our knowledgeable team offers expert guidance on material selection, processing, and application to help you optimize performance and reduce costs.

Our Vision

At Euro Rubbertech International LLC, our vision is to be a global leader in providing advanced engineering plastic solutions that drive innovation, enhance performance, and support sustainable industrial growth across diverse sectors.

Our Mission

Our mission is to deliver high-quality engineering plastics that meet the evolving needs of our customers by combining superior material properties, precision manufacturing, and expert technical support. We are committed to fostering innovation, ensuring reliability, and promoting environmentally responsible practices to empower industries worldwide. At Euro Rubbertech International LLC, we help build a stronger, smarter future with every plastic solution.